Potato Barn

Full Resto

There’s something special about an old barn or historic structure that’s stood the test of time.

At Old Timer’s Barn Rescue, LLC, we believe these structures deserve a second chance. We’re passionate about restoring these beautiful, historic buildings and giving them new life. Restoring the utility of buildings and continuing the heritage of fine detail and craftsmanship in order to match the quality and style of the time period they were created, if so desired.

From siding additions to damaged wood replacement, major structural repairs and full barn renovations or restorations, we have the experience to complete the task methodically and in a concise and detail oriented fashion. With honed skills and “Old Timer” knowledge, we can restore your structure using tried and true techniques and materials. Incorporating subtly installed modern brackets for that original look, or elegant custom fasteners and hardware designed to a desired fashion.

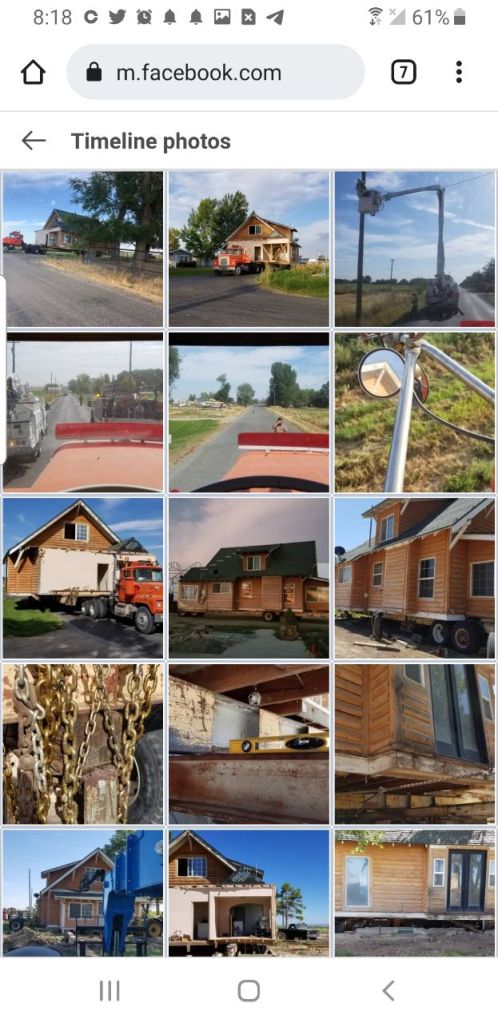

32’x45′ 1917 House Moved 7 Miles in 2019

Lifting to remove structural Tilts, leans, bows, Twists and sags; Or to add new foundations, basements and crawl spaces.

Our experience with moving buildings has allowed us to become experts in structural adjustments and securement. Although no longer an over-road building-moving company. We still offer setback services for buildings moved across private property and lifting services for buildings that need foundation work, basement additions/finishing, floor sag removal or other structural adjustments and repairs.

Specialist Demolition services are also available for everything from agricultural structures and certain industrial facilities and large machines like a printing press or conveyor system removal which does not require abatement. The above photos are from a double wide that had been abated and re-insulated sometime in the early 2000s. Unfortunately it was damaged beyond repair by falling trees during a windstorm.

Picture Above: This is a 70×30, two-story balloon framed, gambrel style barn built in the early 20th Century. It had 18″ of roof spread on 16ft studs, a foundation on the West side only, which had been installed during the 80’s (unfortunately the foundation was not attached to the floor joists and the wall was not leveled before install so complete straightening was impractical, there was max of 8 degrees of lean on eastern exterior load bearing walls with an average of 4 and an average of 3 degrees on the western wall, it was clear that most the barn was drifting and leaning to the East while the foundation held the lower Western exterior wall in place. Finally there was an apparent massive 18″ sag in the roof across the ridge due to the bottom floor joists sinking and rotting compounded by the roof spread being greatest in the mid section.

During the 60’s it had been repaired; new lower rafters and some 2×6 supports were added as well as top of exterior walls pulled in. Unfortunately, due to inadequate supports additions, no rafter ties and using the same spacing with even weaker wood, it began to sag again

.

With the loft loaded with hay and the roof loaded with snow, not to mention the yearly 90mph+ wind during a blizzard. The roof slowly flattened each winter, pushing the walls out at the top and separating the studs from the 2nd floor joists and pulling loft columns off their supports. It is important to note that when constructed, the process for storing hay wasn’t as dense as it is now so it’s fair that they wouldn’t plan for loads it would receive from bails packed and stacked.

After 50 cables over a dozen chains and 27 days of work spread over 7 weeks of slowly tightening and lifting methodically, concrete curing and temporary supports being added and removed; the barn was brought within 1 degree max of plum and within 2 degrees max of level. Now also structurally stable, reinforced and ready to stand another few generations of modern farming.

The surprising realizations, details and speedbumps described below explain why these kinds of jobs are “played by ear“

About midway through to straightening process, we had to remove the previous “fix” since it was installed while building was still in a state of tilting and sagging.

It was apparent they had used too few points of contact. About 7 chains with cable pullers from the looks of the wear on the top-plate and studs that had split from tension loads being applied in too few points and adjusted to rapidly.

They apparently figured that was enough and installed inadequate supports, then removed the tension loads leaving the process to start again.

During the process of our repair and renovation, the walls were pulled in to where originally constructed then reinforced and held with additional columns and framing on the lower floor bearing column framing loads added in the loft.

The roof sag was noticeably and considerably reduced via permanent tension rigging as rafter ties. 140 hurricane ties and diagonal rigging across the rafters installed to prevent raking and drooping, column framing and rafter support, as well as a new foundation was added.

Finally, a proper drainage method to prevent further damage. We even added more framing to first floor to prevent load deflection and allow more hay to be stored during the winter when the snow/dynamic loads are at their maximum.

Pictured Below: (left) Lifting a workshed on existing slab foundation to add a new slab (right) lifted a 100yr old pole barn and moved to other side of the field on new piers.